Cheese Wheel Processing

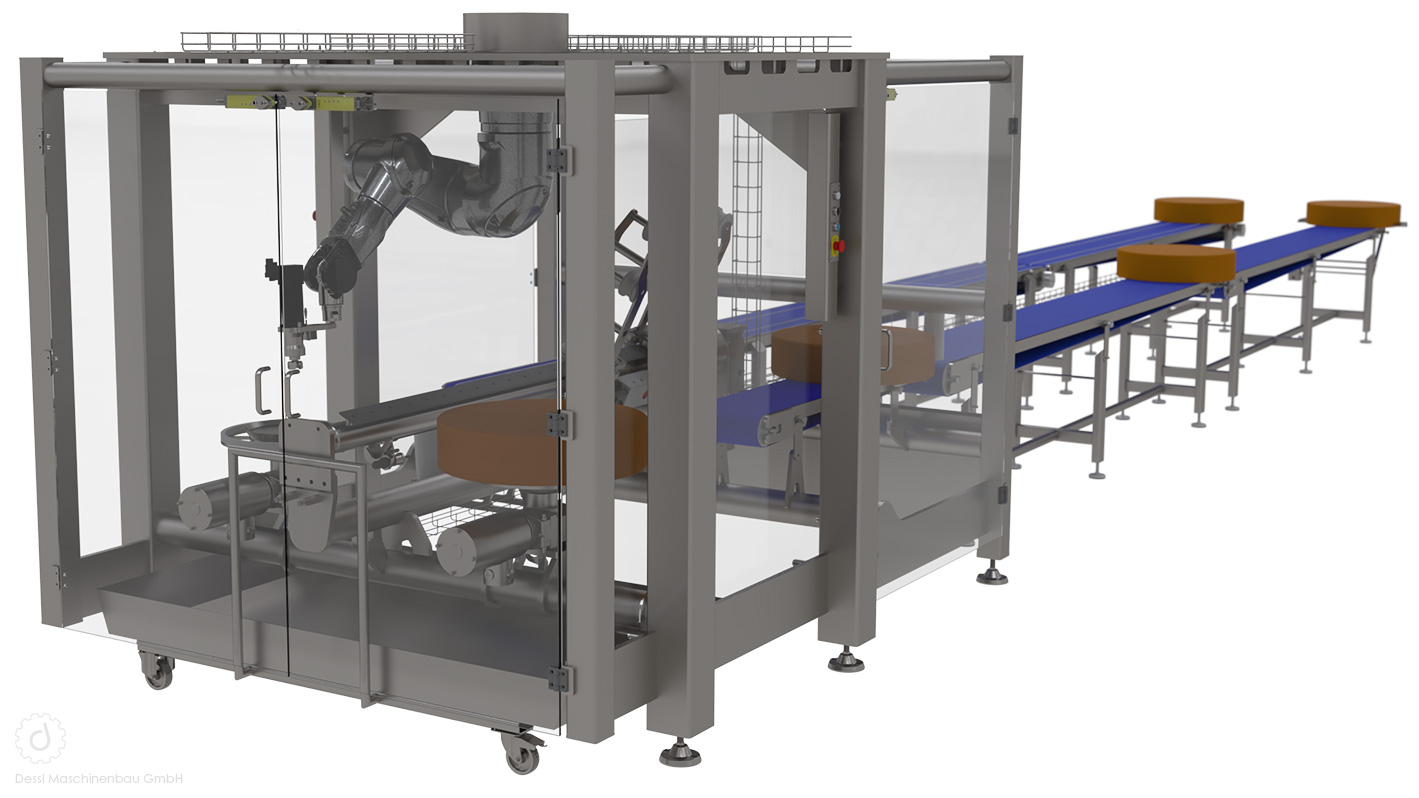

KBA 019 | Automated processing of cheese wheels. De-barking, coating, brushing and more.

The machine design enables the processing, or maintenance, of the cheese loaves on the top and bottom sides as well as on the surface of the jacket. The machine automatically detects whether products are on the conveyor belts or the individual stations, so that loading or unloading is possible at any time during operation. Loading and unloading can be done manually or by palletizing robots.

Debarking is performed by a specially developed milling tool on the robot arm. Food safe and highly precise.

- hygienic design

- optimized for cleaning

- stainless steel drives

- HE robots from Stäubli, specially designed for humid and cleaning-intensive working conditions

- tool change manual or fully automatic

- each cheese is measured by sensors during processing

- infeed depth up to 10 mm, selectable in 0.1 mm steps

- operation via touch panel

- flexible processing of different formats

- manual and fully automatic format selection linked to the storage system

- manual or fully automatic loading

- dimensions (without conveyor) 2.3 m × 2.8 m, height 2.3 m

The Dessl Maschinenbau cheese processing plant

Pictures

The Dessl KBA 019 in operation At KÄSEREI PLANGGER GMBH

Fachartikel:

The magazine AUTOMATION of x-technik reports in its fifth issue 2020 about the cheese processing system developed by Dessl Maschinenbau.

Read the article here (german):