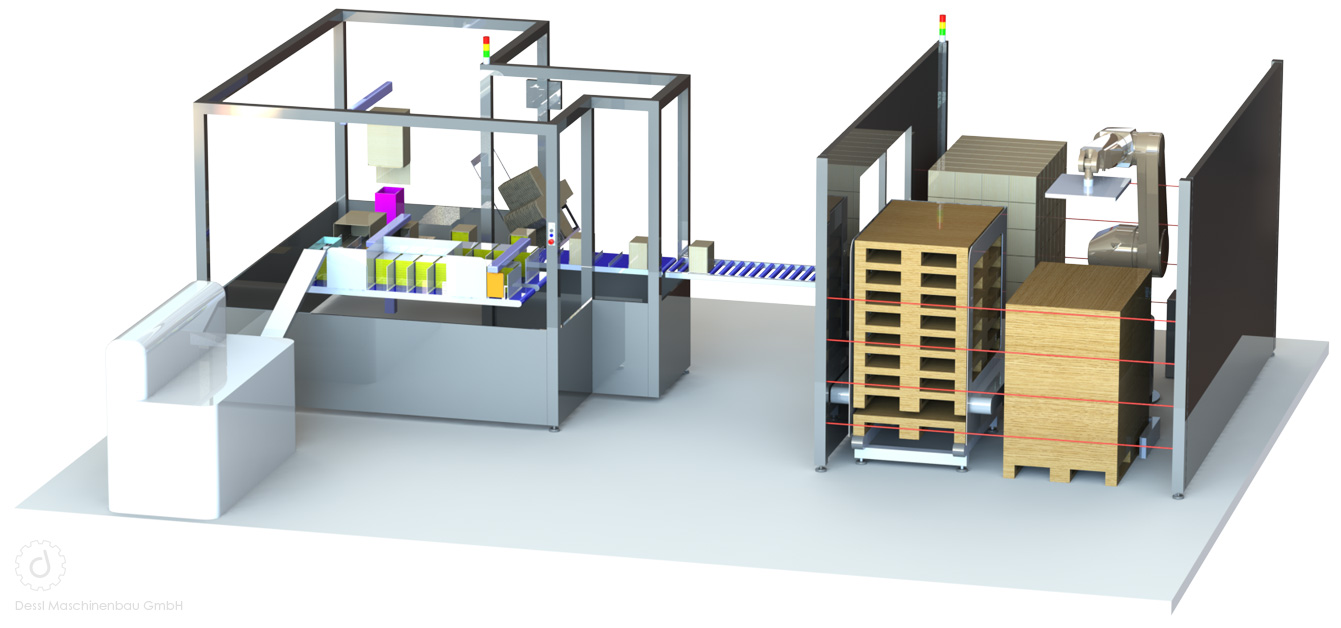

Packaging line for cheese packages

Automated single-variety and mixed packaging (here with connected palletizing system)

Before transfer to the indexing conveyor belt, the cartons are folded and glued. Parallel to the carton erection, the sensor-monitored picking or stacking of the cheese packs takes place. These are fed from the upstream machine via a conveyor belt.

The design of the system allows additional or exclusively manual loading via a safety-sealed area. This ensures variable production of mixed cartons.

The cycle time, from carton removal from the magazine, folding, filling and gluing of the carton, is approx. 5 seconds. This results in a machine output of approx. 750 cartons/hour.